On time Performance

Contries

Machines

Customers

Defect Rate

ISO Certification

Wenext has one of the largest 3D Printing capabilities in the world to fulfil your on-demand manufacturing requirements. From product development to industrial 3D manufacturing, Wenext offers a comprehensive range of rapid prototyping services and technologies. Our range of 3D Printing services includes SLM, SLA, SLS, MJF and Urethane Casting.

Fused Deposition Modeling(FDM) is an additive manufacturing process that belongs to the material extrusion family.

In FDM, an object built by selectively depositing melted material in a pre-determined path layer-by-layer.

Stereolithography (SLA) uses a laser to cure various liquid resins into a solid structure.

SLA produces parts with high precision, smooth, and detailed surface finish.

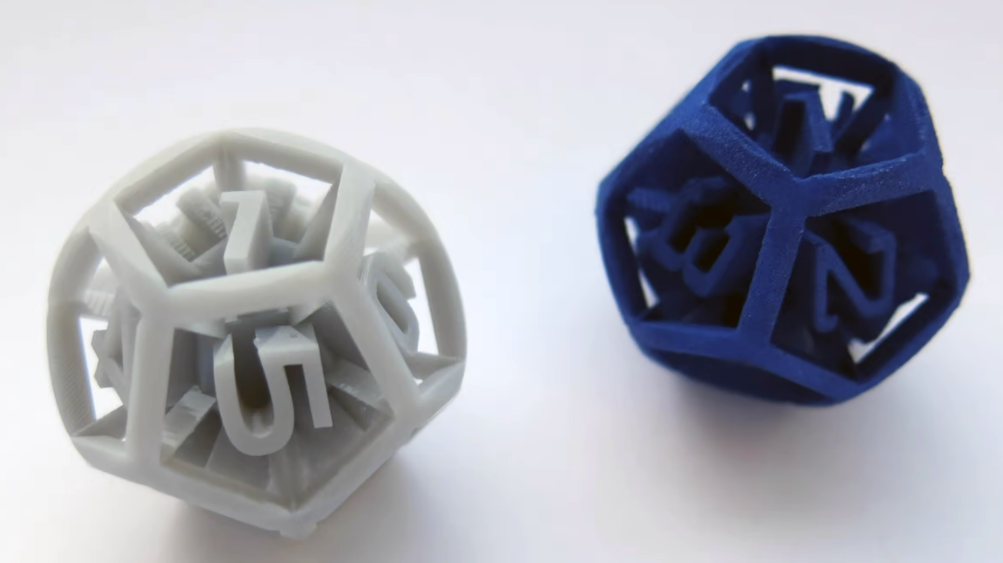

Selective Laser Sintering (SLS) uses a high-power laser to sinter powdered material and build a solid and stable structure.

Parts printed by SLS can work well as functional parts.

Multi Jet Fusion (MJF) uses unique technology and exclusive PA12 material to create strong parts with high dimensional accuracy.

MJF provides high-quality surface finish parts and consistent mechanical properties.

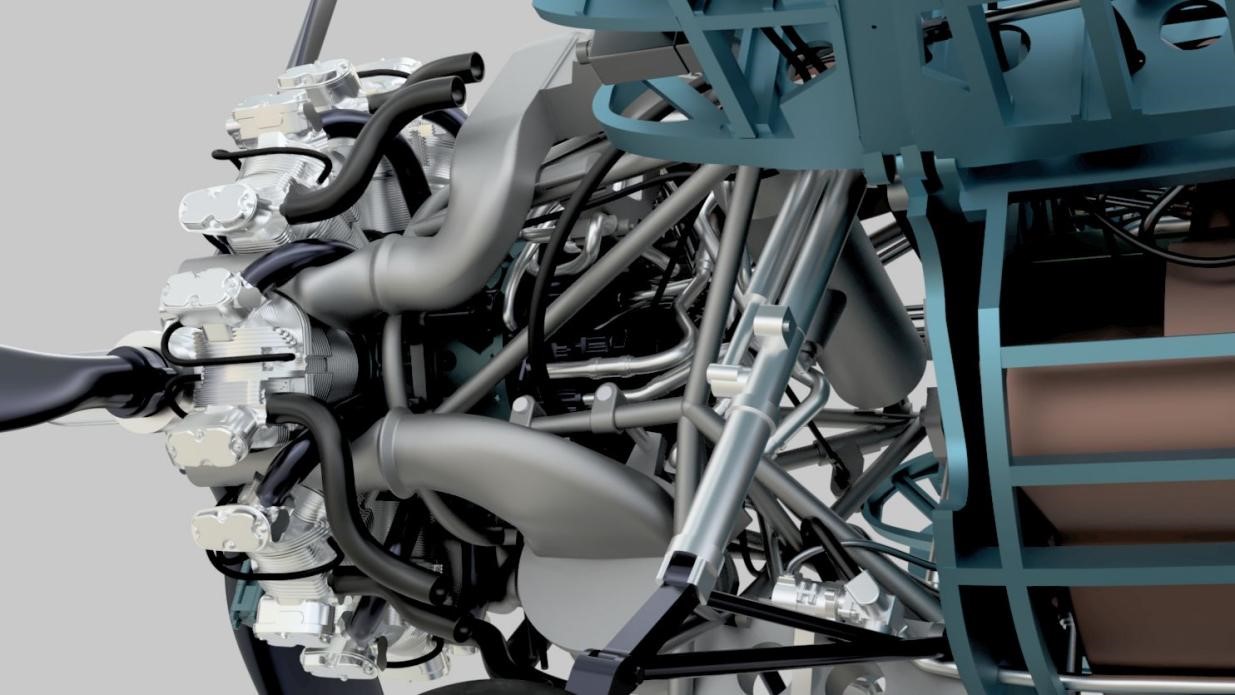

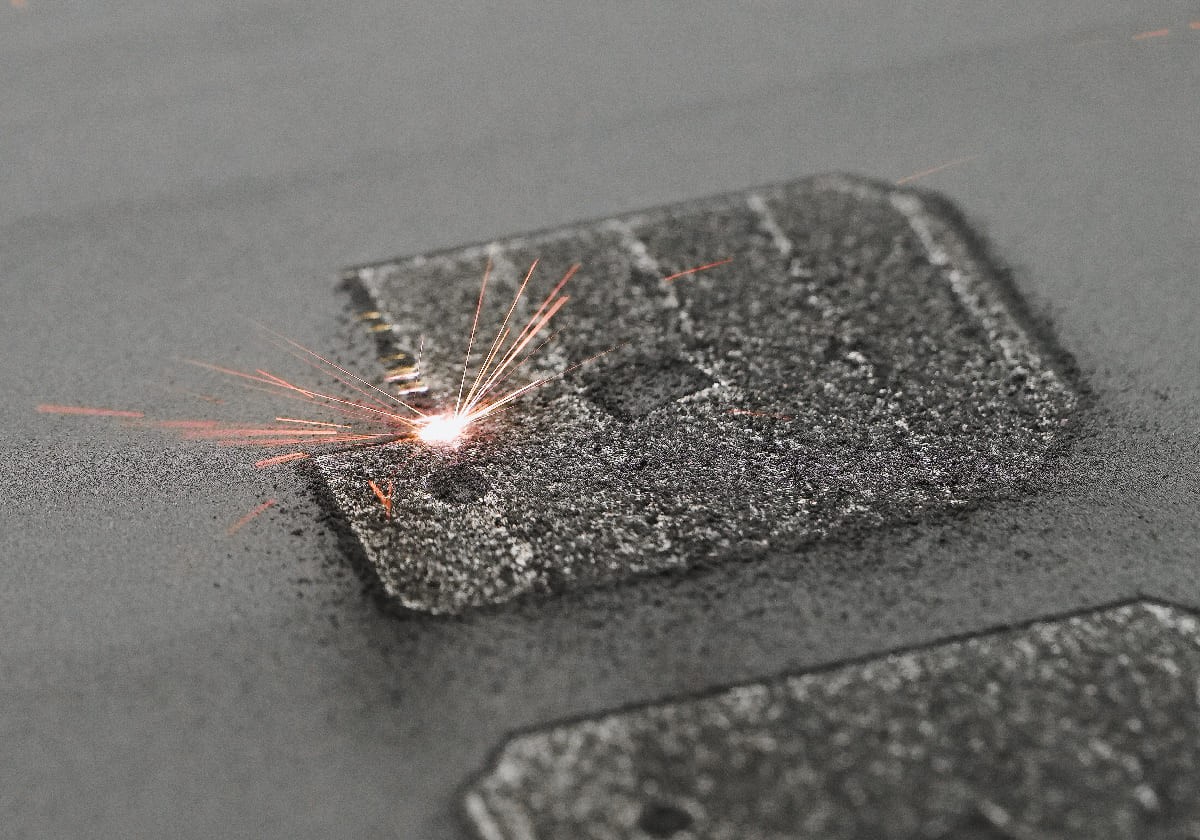

Scanning the metal powder bed with laser light, the powder will be melted and solidified into metal parts.

Parts with complex structures or parts that need to be lightweight designed can be easily manufactured with SLM.

Not sure about which process is the correct one for your part design? Download our 3D Printing Design Guidelines

| SLM | SLA | SLS | MJF | FDM | |

|---|---|---|---|---|---|

| Material Type(s) | Metal Powders | Resin | Nylon and Polypropylene | Nylon | Engineer Plastic |

| Available Materials | 5 | 8 | 4 | 1 | 2 |

| Max. Build Size (mm) | 320 x 320 x 400 | 1650 x 760 x 580 | 350 x 350 x 400 | 370 x 270 x 380 | 1000 x 610 x 610 |

| Min. Wall Thickness (mm) | 1 | 0.6 | 0.8 | 0.8 | 1 |

| Tolerance (±mm) | 0.2 | 0.2 | 0.3 | 0.3 | 0.2 |

| Accuracy | |||||

| Surface Finish | |||||

| Complex Design | |||||

| Support Structures | YES | YES | No | No | YES |

| Pros |

Lightweight design Strong functional parts High density (~99%) Good mechanical properties |

High quality High accuracy Smooth surface finish Functional applications Fast production Complex models Good scalability No wasted materials |

Good chemical resistance Strong functional parts Excellent layer adhesion High strength and stiffness Excellent mechanical properties No support structures require. |

Strong functional parts Accurate printing with fine details Smoother surface compare to SLS Consistent mechanical properties High chemical resistance No support structures require. |

Strong functional parts Accurate printing with fine details Smoother surface compare to SLS Consistent mechanical properties High chemical resistance No support structures require. |

| Cons |

Post-processing is necessary for high quality surface. Spheroidization and warpage might occur. |

The material is sensitive to long exposure to UV light. Parts are affected by moisture, heat, and chemicals. Material is limited to photosensitive resin. |

Rough surface finish Limited material options |

Limited material options | Limited material options |

| Applications |

Metal prototypes Parts require complex structure Lightweight design Topology optimization Small-batch production for metal parts Mold conformal cooling channel |

Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Modelmaking |

Functional prototyping Short-run, bridge, or custom manufacturing |

Functional prototyping Short-run, bridge, or custom manufacturing |

Functional prototyping Short-run, bridge, or custom manufacturing |

Upload your CAD to our online quoting system.

Upload your CAD to our online quoting system.

Configure Your Parts Specification.

Configure your part specifications and select the best material for your order.

Quality Control and Delivery.

Order complete and make sure your parts are manufactured according to our standards.

Somos® Tough Resin

Somos® GP Resin

Somos® Tough Resin

PA12 White

Somos® GP Resin

AlSi10Mg

We can generate instant 3D printing quotes for 30+ plastics and 6 metals. Each material takes different lead time, not sure about which material is the correct one for your design? Download our material description.

Somos® LEDO

Somos® GP Resin

Somos® WaterShed XC 11122

Somos® Tough Resin

Somos® Taurus

Somos® Imagine Black

Standard Resin

Tough Resin Green

PA12 White

PA12 Black

PPGB Glass-filled

PA12 Glass-filled

HP PA12 Black

HP PA12 Gray

17-4 PH Stainless Steel

SUS316L

We provide a wide range of surface finishing options, making it possible to achieve the desired outcome.

Threading

Insertion thread is a metal fastening element that is inserted into an object to provide a threaded hole for fasteners such as screws or bolts.

Tapping

Tapping is a machining process of cutting a thread inside a hole to produce internal threads.

Sanding

Sanding is a process to smooth the printed part and remove blemishes and leftover support marks.

Polishing

Process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment.

Painting

Color printed part according to your desired outcome by selecting from the Pantone color chart.

Upload your files, get instant quote. No hidden costs.

Self-operated workshop, one-shop production service.

From customer care manager to technical support, wenext puts the quality of your output first and provides high quality service to ensure you receive a satisfactory product.

3D Printing Factory

SLA Factory

MJF Factory

MJF Factory

SLM Factory

SLS Factory

The Best 3D Model Sites for 3D Printing Mechanical Parts

July 13 2022

To help engineers find designs of mechanical part models, we list the best sites for 3D Printing mechanical parts.

Read Article

Introduction to SLM 3D Printing Service

May 17 2022

As one of the major parts of metal 3D Printing, SLM plays an important role in nowadays manufacturing industry.

Read Article

SLA vs SLS: The Differences - Simply Explained

June 23 2022

SLA vs SLS, both 3D Printing technologies are using laser to create solid objects, learn the differences between SLA and SLS in the article.

Read Article

Nylon 3D Printing: Materials and Technologies

July 19 2022

Nylon is a common material that can by applied in different 3D Printing technologies, discover and learn bout nylon 3D Printing in this article.

Read ArticleHave you noticed that some natural landforms are the deposition of sand, wind, or water, like sand dunes. Imagine the wind is blowing, and water is flowing; sand becomes a sand dune layer by layer. Is this a process of shaping a three-dimensional object? If so, what if we can print a three-dimensional object layer by layer directly, just by a printer? In the 1980s, printing a 3D model by a printer came true as printing equipment and materials developed.

3D Printing is one of the Rapid Prototyping technologies. It can print three-dimensional objects based on CAD models or digital 3D models under the control of a 3D printer. It is the process of printing an object by adding materials layer by layer, which is called Additive Manufacturing. Assume that 3D Printing is similar to printing files from a printer but using different technologies. For printing a piece of paper, you need a Word, PDF, or Excel document, which are all 2D. While printing an object, you will need 3D model designs in STL file format and 3D printable materials. When 3D models, STL files (need to convert into G-code through a slicer software), and 3D Printing materials are ready, 3D printer is being able to print the design layer by layer.

Distinguished from traditional manufacturing process, 3D Printing is a process of adding materials to create a product instead of machining on a block of material. The additive nature makes 3D Printing a unique manufacturing method, which is typically fast with relative low setup costs. 3D Printing can create more complex geometries than traditional manufacturing techniques, which has been utilizing in the engineering industry widely, particularly for prototyping and creating complex/ lightweight geometries.

3D Printing is connecting with engineers, designers, hobbyists, and, amateurs, gaining popularity in the make culture. Available low-cost printing material, accessible printing techniques like FDM, and affordable desktop 3D printers (such as MakerBot, Ultimaker, and Formlabs), are largely facilitate 3D Printing technology to grow fast.

Besides, there are different 3D Printing services such asStereolithography (SLA),Selective Laser Sintering (SLS),Multi-Jet-Fusion (MJF), and Selective Laser Melting (SLM) to enable you to prototype resin/ nylon/ metal parts.

1. When will my order ship?

2. Is my 3D model printable? Which 3D printing method is best for it?

3. Which material should I choose?

4. What are your standard tolerances and manufacturing standards?

5. I don’t have a 3D CAD model. Can you create one for me?

CNC MachiningLearn more

Vacuum CastingLearn more

Copyright © 2023 Wenext, All Rights Reserved

This website uses cookies for better personalized services. By using our websites, you agree to this use. Privacy Policy

We use cookies to improve your experience, check out Privacy Policy.