Design Guideline - CNC Machining

CNC Machining Design Guidelines

Is my online purchase secure?

CNC Machining is a popular choice for producing industrial parts because the process is highly versatile, repeatable, and reliable — plus, it is compatible with a broad range of materials. Variables in relation to the functionality of CNC models differ from one CNC type to the other.

Please Note: Below value is only recommendation for best CNC design practices.

File Format

Wenext supports up to 10 multiple files upload, size of each individual file should not exceed 64MB. Recommend format is STEP(.step / .stp) file

Material Consideration

Please consider the following when selecting your material as it will significantly affect machining cost:

1.Part Size

2.Material Hardness

3.Material Characteristics

4.Finishing Aesthetics

Tolerance

Please use standard tolerance when designing your drawings. Wenext standard tolerances is 100um, 50um, 25um. Tolerance could reach 2um though EDM, WEDM and Wire Cutting.

Size Limitations

Part size is limited by machining's capabilities. Machining costs are greatly affected by part size. Normally, the larger the part size, the greater the cost.

Milling maximum size: 1000*600*600mm

Turning maximum size: 800*250*50mm

Corners

Milling is done with circular drill bits, hence it is difficult to achieve sharp internal corners. It Is recommended to add a radius while designing inner edges and must be larger than the cutter to be used. The radius of the corner will be 1.3 times the milling tool radius as your inner edge radius.

Walls Thickness

Parts with very thin wall thickness could stress on the material and machine which will cause vibrations during machining and decrease the accuracy. In the other hand, using moderate and standard wall thickness will improve strength and accuracy of CNC process. Suggested thickness of your workpiece should be greater than 0.8 mm.

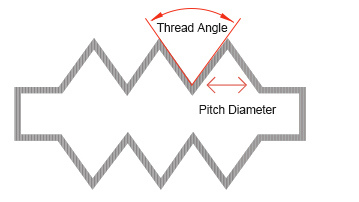

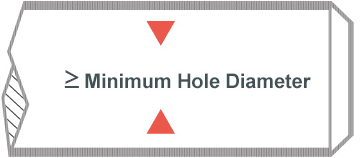

Holes

Hole Depths: suggested no more than 4 times the nominal diameter

Hole Diameters: standard drill bit sizes

Text

Engraved feature is less expensive than embossed feature as less material is removed. Ensure depth and width is at least 1mm diameter to ensure clear and easy reading.

Tolerances | 0.005 (±mm) | 0.003 (±mm) | 0.005 (±mm) |

Maximum Size | 1000x600x600 mm | 500x400x300 mm | 1000x600x600 mm |

Minimum Size | 6.35mm x 6.35mm | 6.35mm x 6.35mm | 6.35mm x 6.35mm |

Cavity Depth | 4 x cavity width | 4 x cavity width | 4 x cavity width |

Internal Edges: Vertical Corner Radius | ⅓ x cavity depth (or larger) | ⅓ x cavity depth (or larger) | ⅓ x cavity depth (or larger) |

Minimum wall thickness | 0.8 mm (metals), 1.5 mm (plastics) | 0.8 mm (metals), 1.5 mm (plastics) | 0.8 mm (metals), 1.5 mm (plastics) |

Hole Diameter | standard drill bit sizes | standard drill bit sizes | standard drill bit sizes |

Hole - Maximum Depth | 4 x nominal diameter | 4 x nominal diameter | 4 x nominal diameter |

Minimum hole diameter | 2.5 mm (0.1'') | 2.5 mm (0.1'') | 2.5 mm (0.1'') |

Text & Lettering | Recommend 5 mm engraved | Recommend 5 mm engraved | Recommend 5 mm engraved |