Discover FDM 3D Printing and learn the differences between FDM 3D Printing and SLA 3D Printing.

You may be wondering how those exquisite decorations are created by 3D Printing, and what kind of 3D Printing services are widely used in our daily life. So, in this article, we will introduce FDM 3D Printing to you.

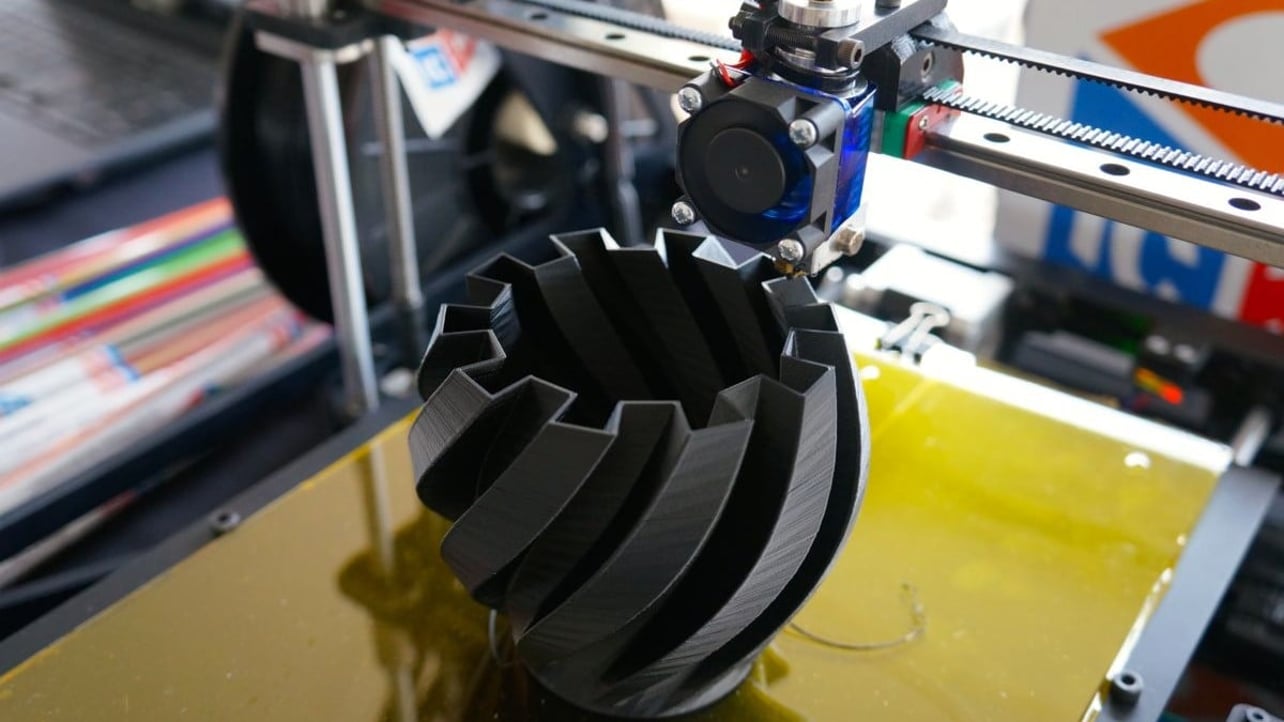

Image Source:All3DP

In this article, we will introduce what is exactly FDM 3D Printing in an easy-to-understand way, FDM 3D Printing advantages and disadvantages, and the comparison between FDM 3D Printing and SLA 3D Printing.

FDM, as known as fused deposition modeling, is one of additive manufacturing processes that fuse and melt thermoplastic filament such as ABS, PLA and wax layer by layer. FDM is the same 3D Printing technology as FFM (Fused Filament Modeling) and FFF (Fused Filament Fabrication). The filament is heated and melted through the hot nozzle and extruded in a pattern. After hot extrusion, the filament is deposited on the previous layer of solidified material, and the print bed goes down at designated parameters so that the layers can be fused together.

The reason why FDM is one of the most widely used 3D Printing services is that it owns some advantages that other services don’t have.

1. Material flexibility. There are a variety of printing materials that FDM 3D Printing can use, including PLA, ABS, nylon, paraffin, casting wax, artificial rubber and even metals and ceramics materials with low melting point.

2. Cost-effective. As FDM printers are cheaper than other 3D Printing machines, to buy an FDM printer is affordable. And we list 10 best FDM 3D Printer for you. Besides, the FDM printing materials are easy to reach, which makes FDM a cost-effective additive manufacturing.

3. Less post-processing. The support structures of FDM printed parts are easy to remove. And later, water-soluble filament showed up, making it easier to remove supports of FDM printed parts.

However, there are disadvantages if you choose FDM as well.

1. Only suitable for simple and small-sized parts production. Because the capabilities of FDM 3D Printing is limited, and the part’s size produced by FDM is small. If you want to print something large, you wouldn’t consider FDM.

2. Rough surfaces details. By melting thermoplastic filament and put it layer by layer, it will make the layer texture very obvious.

3. Unstable quality. The layer thickness is not strong, which means the mechanical properties of FDM printed parts are unstable and durability cannot be guaranteed. Therefore, the applications of FDM parts are limited.

SLA, also known as Stereolithography, is a 3D Printing technology that use UV laser light to cure liquid resin layer by layer, and eventually create a solid object. To help you choose between FDM and SLA, we will also list advantages and disadvantages of SLA.

SLA has been commonly used in various industries since 1980s, there is no doubt that SLA 3D Printing has advantages that those industries love it.

1. High quality. The biggest difference between FDM and SLA printed object is the printing quality. As SLA printer use liquid resin and laser light to 3D print an object, the object is with higher precision than FDM printed parts. Therefore, SLA printed parts can be used as model display and prototypes.

2. Smooth surfaces. As SLA uses laser to cure liquid resin and form a solid object, while FDM fuses filament together, the surface of SLA printed part is smoother.

3. High efficiency. Obviously, using laser light and melting filament, the working speed of SLA 3D Printer is faster than FDM. You can create a real object efficiently by SLA.

Nevertheless, every coin has two sides. And SLA is no exception.

1. Cost is higher than FDM. Compared with FDM printer, buying SLA printer will cost you higher budget. Besides, the maintenance cost is higher too.

2. Limited printing materials. As the most commonly used material of SLA is liquid resin, and the color of resin are normally white, black, and yellow. Your choice of printing materials and printing colors are limited.

3. Post-processing can be complex. SLA printed parts can be in complex structure and larger size, it takes much time to deal with post-processing such as supports removal, sand blasting, and model curing.

As mentioned above, both FDM and SLA have benefits. To define which is better and which is to use is based on your demands. If you are looking to create your object from design, manufacturing to small batch production with lower cost, FDM is suitable for you. If you need a fine model to showcase your design, SLA enables you to create an exquisite final part.

Wenext, as one of the leading AM companies in Asia, is dedicated to delivering one-stop online 3D Printing services to global customers. Wenext provides a wide range of 3D Printing services, and SLA 3D Printing is one of the best. SLA produce parts with high precision, smooth and detailed surface finish, and Wenext has a wide range of resins to support you to create a fine model.

With the manufacturing capabilities of more than 300 SLA 3D printers, Wenext are being able to satisfy your demands at any time! More importantly, what Wenext offers is online SLA 3D Printing, you can upload the CAD designs on our website directly and get instant quote, we would like to deliver 3D printing services to you as easy as online shopping!

Please feel free to try instant quoting on our website or contact us hello@wenext.com if you are interested.

The integration of 3D printing has not only sped up the design process but also introduced unprecedented flexibility and innovation into the automotive industry

With its unique advantages, SLM metal 3D printing has emerged as a solution for manufacturing intricate metal structural components.

New materials and new technology make 3D Printing silicone possible now! Discover more in this article!

See what toys you can 3D print for your cats, check out the best 3D printed cat toys of 2023 here.

The integration of 3D printing has not only sped up the design process but also introduced unprecedented flexibility and innovation into the automotive industry

With its unique advantages, SLM metal 3D printing has emerged as a solution for manufacturing intricate metal structural components.

New materials and new technology make 3D Printing silicone possible now! Discover more in this article!

See what toys you can 3D print for your cats, check out the best 3D printed cat toys of 2023 here.

Want to make 3D printed jewelry for yourself or gain inspirations from jewelry 3D models? Check these jewelry STL files out!

Whether you own a jewelry business or not, additive manufacturing play an important in nowadays jewelry industry. Check out reasons to choose 3D printed jewelry in this article!

In this article, we’ll learn about CNC laser cutting to help you choose the right manufacturing service.

CNC machining has two types, CNC milling and CNC turning, and we will introduce three types of CNC milling machines in this article.

Here is the ultimate guide of 3D Printing support structures, learn more and eliminate warping in every printing experience!

Check out what is titanium anodizing and how to anodize titanium.

.png)

We have listed ten excellent 3D modeling apps for you. Some are android modeling apps; others are iOS 3D modeling apps.

Check out the best carbon fiber 3D printers from desktop level to industrial level, and make your carbon fiber parts easily!

Copyright © 2023 Wenext, All Rights Reserved

This website uses cookies for better personalized services. By using our websites, you agree to this use. Privacy Policy

We use cookies to improve your experience, check out Privacy Policy.