Description: 3D Printing delivers scalability and flexibility to drone manufacturers, customizing specified drone parts, more flexible designs and small batches are available.

Written by Abigail 2022-12-27

|

Category |

Drone |

|

Product |

Drone Frame and Internal Parts |

|

Application |

Prototypes and End-use Parts |

|

Process |

SLS |

|

Material |

PA 12 Black & PA 12 White |

Industrial Insights

3D Printing is primarily used for rapid prototyping and visual testing, and having great impact on multiple industries. However, the technology is used to make end-use parts increasingly. In drone industry, 3D Printing is being used widely for building the drone frame, gears, camera mount and protective equipment, etc. 3D Printing delivers scalability and flexibility to drone manufacturers, customizing specified drone parts, more flexible designs and small batches are available. Start-ups and enterprises gain lots of benefits from the technology. Besides, with 3D Printing, it is easy that manufacturers can achieve light weight design for building drones. We believe that more and more companies will acknowledge the capability of 3D Printing.

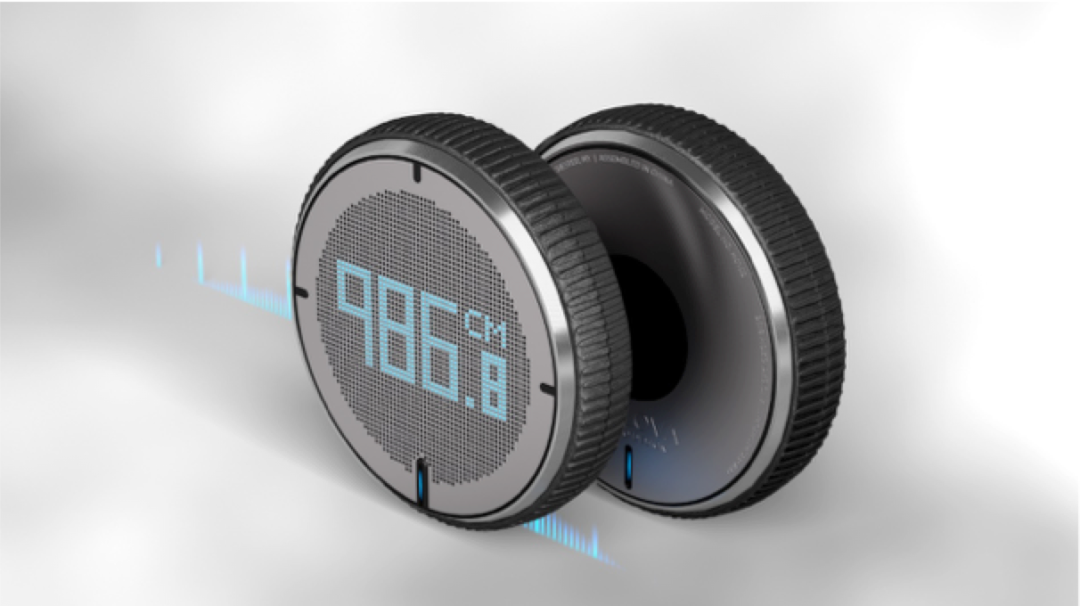

Image Source: Entronic Tech

How to Manufacture

SLS is utilized to make the drone parts, including drone frame, fans mount, and the protective equipment. The major reason of using SLS is that the technology offers durability and good mechanical properties to the final parts. Due to the drones are used for light shows, we recommended that nylon is the material to choose. Nylon allows light weight design and transmission of light. It is no doubt that 3D Printing allows complex geometries and structural designs, printing complex internal components is why we use SLS 3D Printing. However, printing hollowed-out part could be extremely difficult, especially when it is used as protective shell for the drone. We tried and adjusted different printing angles, and shipped the hollowed-out part with special packaging. All parts and components were intact when our customer received it.

Image Source: Entronic Tech

What to Offer

We have been cooperating with our clients on drone project since 2018, most of the drones are made for light shows. We have close relationship with our customer and provide reliable and cost-effective solution to make each part. When printing the hollowed-out part with large size, we adjusted the printing angles to save cost for our customer; when we checked the printing files detailly, we offered our solution to optimize the designs and make the files more printable. We strive to deliver the best on-demand manufacturing solutions and services.

Image Source: Entronic Tech

HOZO Design team works with Wenext for product verification process which helps to reduce cost and expedite the product life cycle.

What is RC? It is the famous remote control model car, referred to as RC car (rc=remote control) - a cool toy for big boys!

©2019-2025 WeNext Technology Co., Ltd. All Rights Reserved.

This website uses cookies for better personalized services. By using our websites, you agree to this use. Privacy Policy

We use cookies to improve your experience, check out Privacy Policyy.