Description: With 3D Printing, it is easier to test reliability of the design and boost production cycle for critical communications industry.

Written by Abigail 2023-01-12

|

Category |

Critical Communication and Device |

|

Product |

Explosion Proof Mining Lamp |

|

Application |

Product Verification |

|

Process |

SLA and Vacuum Casting |

Industrial Insights

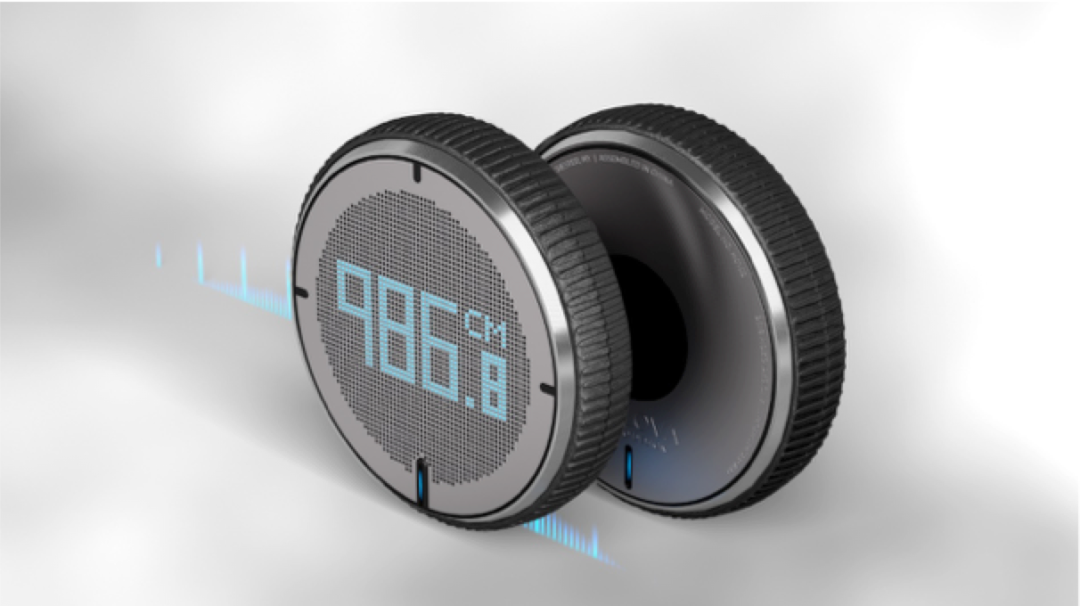

3D Printing is considered as a versatile manufacturing technology that it showcases the capability and usability in most of industries nowadays. Before this, it is difficult to find the connection between 3D Printing and critical communication industry. Rapid prototyping with low cost is the key benefit when using 3D Printing for product verification. Critical communication equipment can be complicated in designs and mass production. With 3D Printing, it is easier to test reliability of the design and boost production cycle for the industry. Explosion proof mining lamp (safety lamp) is one of the most important devices for mining critical communication as the top priority is to keep seamless communication amongst works and protect workers from dangers. We are familiar 3D printed lamp, but how about 3D printed mining lights?

How to Manufacture

The 3D printed mining lamp is used as product verification. The ultimate purpose is to use the 3D printed model as mold and use injection molding for batch production. We used SLA and vacuum casting to make mining lamp parts, including the frame, small components, and shell. SLA is one of the most accurate 3D Printing technologies to produce parts with smooth surface finish. Standard resin is the material due to its good material performance as ease-of-post-processing, high precision, and good strength. Assembly is required for the final parts. Therefore, we ought to avoid any damages in the post-processing procedures. Besides, painting the shell and frame red is what our customer asked for, and Pantone 1797U met the needs. Vacuum casting and TPU are combined to make those comfort-to-press and quick-respond button. We deliver customized manufacturing solutions case by case. While fast, flexible and durable were what our customer seeking for, we recommended 3D Printing and vacuum casting.

Image Source from Our Customer

What to Offer

By receiving 3D models of the product from our customer, the first task is helping our customer to check the printability and we will help our customer enhance designs to ensure successful printing. “Every detail of the design and which part needs to be amended were clearly indicated. You just did everything great!” Our customer satisfied with our service as we are professional in every step. The good quality of the final part and fast lead time also impressed our customer, so they are planning to work with us again in the following projects. And hopefully we can work on more critical communication project.

HOZO Design team works with Wenext for product verification process which helps to reduce cost and expedite the product life cycle.

What is RC? It is the famous remote control model car, referred to as RC car (rc=remote control) - a cool toy for big boys!

©2019-2025 WeNext Technology Co., Ltd. All Rights Reserved. 备案号:粤ICP备14084727号

This website uses cookies for better personalized services. By using our websites, you agree to this use. Privacy Policy

We use cookies to improve your experience, check out Privacy Policy.